sheet metal drawing standards

9981870 - Drawing Compounds Water Based for Sheet Metal January 1 2020 - GMNA Material Description. D 25T R see below The height can be less but it required secondary operations and is far more costly.

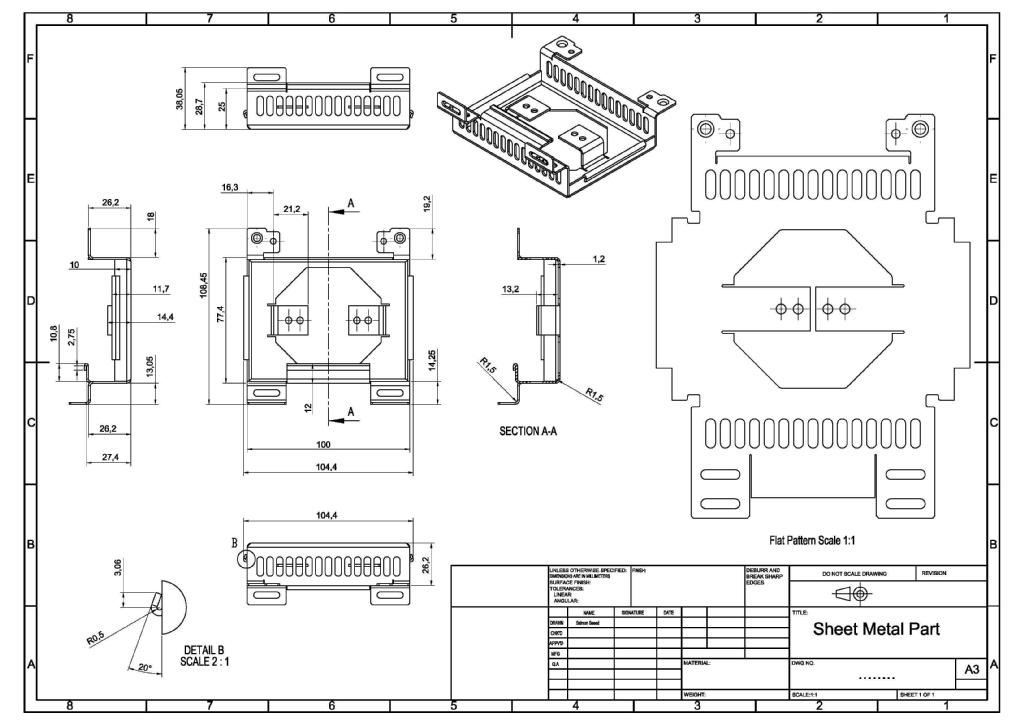

Freelance Sheet Metal Design Services For Companies Cad Crowd

Standard in which case AS SHOWN should be noted on the drawing.

. Uniformity If your order requires exact duplication of materials shapes and cut ISO standards help make that happen. Raw Samples Delivered on Time or Your Tooling is Free. Ad Decrease tooling cost and lead times with Quintus metal forming presses.

This PDF lists information needed for the title sheet. Metal Stairs - General Notes Optional Use temporarily withdrawn. We typically use C2680 for sheet metal forming.

Drawing upon the considerable experience of its own CADD Task Force. Sheet metal drawing standards. They should be of a suitable size and not less than 3mm tall.

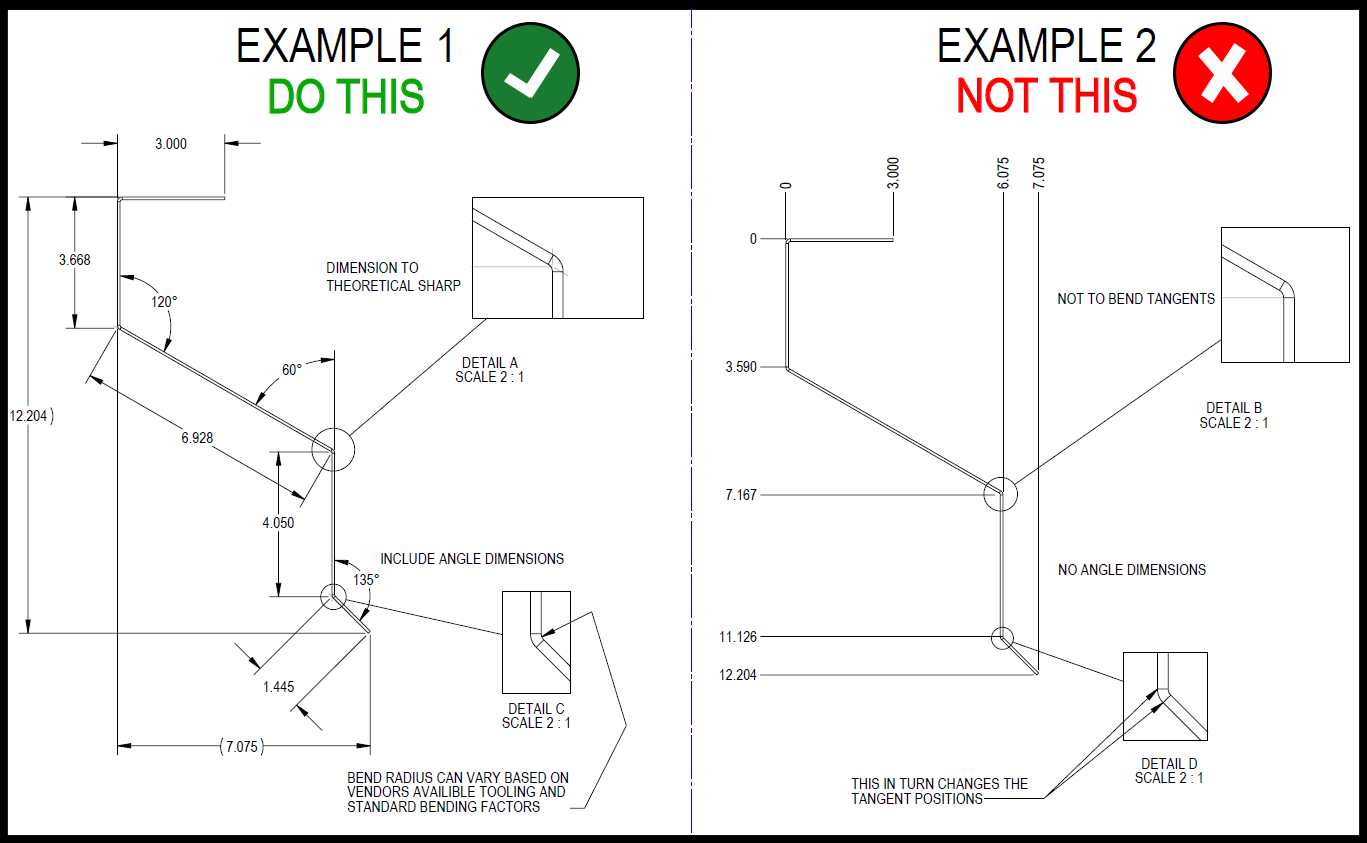

The variation becomes larger as the bend angle increases and the part will no longer pass inspection. They should be legible and clear especially numbers as they often have to be read on their own. Lower-left corner of the drawing sheet touching the left and bottom border lines 3.

Ad Realistic Sheet Metal Stamping Solutions For All Complex Applications. Hansen Steel holds all of the standard sheet metal sizes in stock in our. Most-Recent Revision Only Clear all.

These factors all play a role in why most manufacturers dont want you to dimension parts in the flat pattern. All drawings require some form of lettering and numbers. Hansen Steel is a leading metal distributor and sheet metal fabrication company in Los Angeles California.

Contact Us Today Get Started. Select the Bend Extremities tab. The ordinary rules and conventions in use in mechanical drawing apply in general to sheet metal drafting.

BRASS Low carbon steel contains 005-032 carbon compared to medium high and ultra-high carbon steel. Sheet metal is one of the shapes and forms metal can be bought in. Grading and BMP General Notes 03282017.

PDF CAD Title Date. Sheet metal is any metal that has a thickness in between 056 millimetres. Copper an alloy of copper and zinc brass is very ductile and corrosion resistant.

Most-Recent Revision Only 260 Not False 0 Publisher. General Tolerances ISO 2768-1. Sheet metal shops can bend to around -015 accuracy.

Easy Tool Modification Shorter Lead Times And Lower Tooling Cost With Quintus. If You Need Speed Capabilities Quality Control For Your Next Project Call Us. Name and address of the project owner applicant engineer surveyor etc.

The principles to remember are. Click the Sheet Metal Parameters icon. But what makes these guidelines so beneficial to customers like you.

Drawing Number Sheet Rev. The Sheet Metal Parameters dialog box is displayed. To the left of the title block touching the bottom border line and the title block.

The company offers an array of custom and intricate designs and applications used for column covers panel systems louvers roofing - all using metals such as pre-finished aluminum pre-finished steel copper and other metals as specified by. 215 On detail drawings with 3 or more hole sizes holes shall be tabulated using the label shown. Enter 1mm in the Thickness field.

When considering sheet metal thickness a single sheet with punches holes is a good rule of thumb. To the left of the title block touching the bottom border line and the title block. Ad Get A Fast Quote On Any Custom Metal Manufacturing Project.

Narrow Your Results Revision. Millimetres Mils Gauge. Sheet metal material selection is an iterative process.

If you tell them to do -005 they are either going to ingore your tolerances or they are going to have to clean things up in the machine shop somehow. ASTM 11 SMACNA 9 MPIF 11 ICBO 1. Sprinkler System Riser Detail -Wet Pipe temporarily withdrawn.

We provide aluminum and steel distribution and processing services to Southern California and surrounding areas. Defining the Sheet Metal Parameters This task shows you how to configure the sheet metal parameters. Upper-left corner of the drawing sheet touching the top and left border lines 2.

Many sheet metal workers are educated and certified in two popular standards -- ISO 9001. Form height to thickness ratio To determine the minimum form height for sheet metal use the following formula. However once you expand over all four bends that number increases to a difference of 130 on the overall flat length of the part.

Recommended Distance Radius of Hole1 Radius of Hole2 Sheet Thickness Effect of Grain Direction in Sheet Metal Bending Grain Orientation in sheet metal Parts. For high quality sheet metal look to Hansen Steel. Foils sheets and plates are pretty much the same with the only difference being in thickness.

This specification details the requirements for water based drawing compounds that provide additional lubricity to aid in metal forming operations and must be compatible with current production processes and paint systems. This video demonstrates how to properly dimension a sheet metal layout technical drawing. Standard Drawings Details STD-342-400.

216 For slots callouts for CENT TYP and RADIUS or R are assumed. There are other measurement units used to categorise metals by thickness though. Before attempting to make any drawings one must first get a clear idea of the way in which objects are represented in mechanical or orthographic drawings.

A knowledge of elementary arithmetic is also essential. Why ISO Matters in Custom Metal Fabrication 1. 214 All tapped holes are assumed to have coarse threads unless otherwise specified.

Above the title block touching the right border line and the title block 4. Sheet Metal Drawing Standards 81-100 of 260 results 20 results per page 10 results per page 30 results per page 50 results per page 100 results per page Filters. Enter 5mm in the Default Bend Radius field.

JHG Huntress Mechanical OP 25 Jun 03 1157 Drawoh. It applies for the linear dimensions and angular dimensions such as external sizes internal sizes step sizes diameters radii. Above the title block touching the right border line and the title block 4.

The recommended minimum distance between two hole centers in sheet metal design should be equal to the sum of hole radius plus two times the sheet thickness. Generally capabilities of of 09mm 20mm in thickness are able to be manufactured from sheet 3mm but this tolerance depends mainly on the part. 2015 and AS 9102.

Depending on the quantity of zinc in the alloy. Sheet Metal Drawing Standards - 17 images - portal frame dwg section for autocad designs cad ceramic tile t bar transition strip ceramic tool company structural steel detailing invetive in melbourne we space truss steel structure dwg detail for autocad. There is no standard title block for grading and drainage plans for privately maintained improvements within private properties.

This makes low carbon steel a more cost-eective choice. They are going to consider the fact that the lowest bid gets the job. Weiss Sheet Metal the parent company has continued as a contractor and manu- facturer of basic sheet metal products.

It reviews general dimension standards as well as requirements for. This gives brass sheet a wider range of performance depending on end use of the designed part. ISO 2768-1 is intended to simplify drawing indications and specifies general tolerances in 4 tolerance classes f fine m medium c coarse v very coarse.

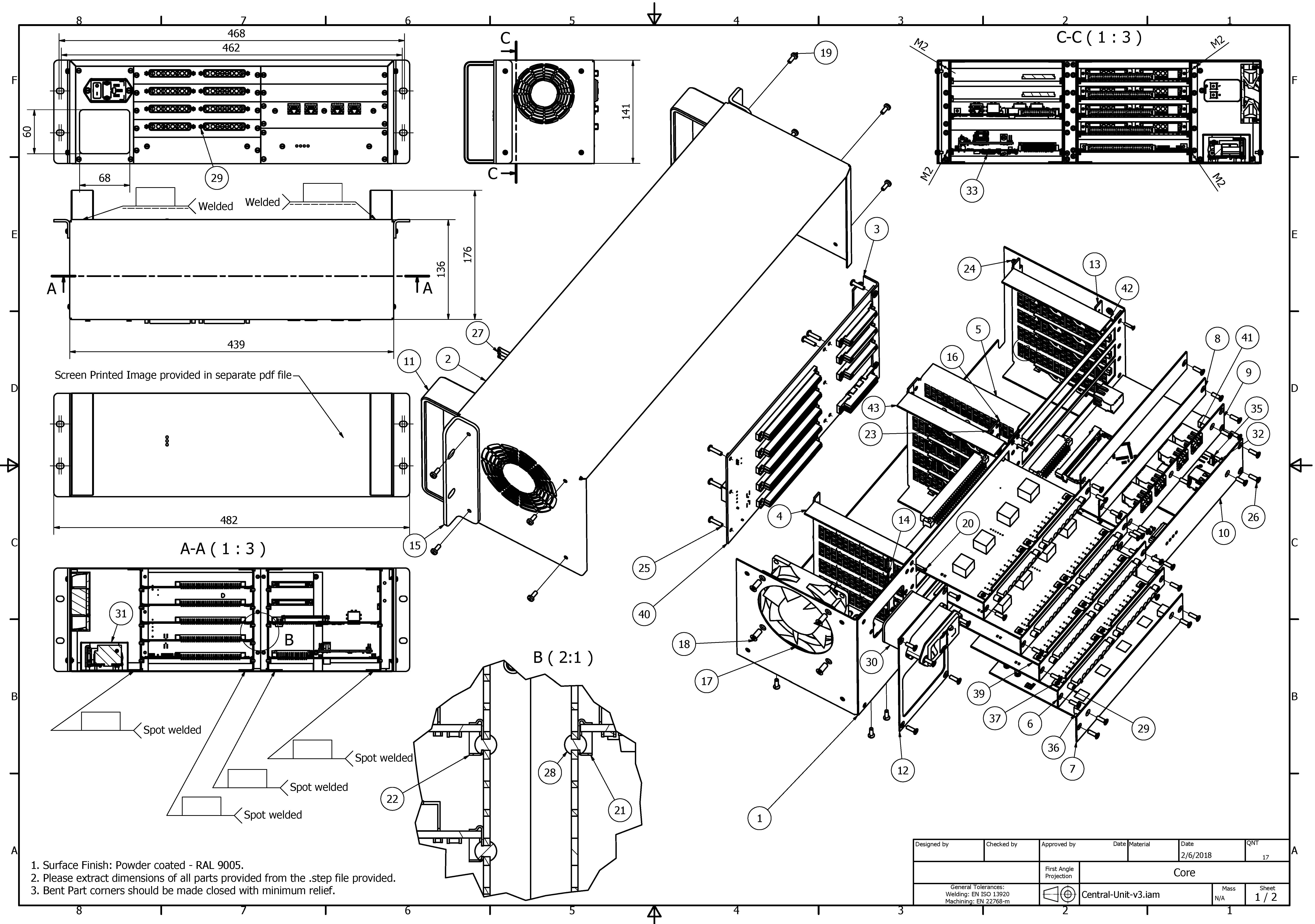

Contact POC for latest draft 9804. SCS articulates the CAD standards that will enable SMACNA members and the rest of the AEC community to apply CAD effectively to mechanical fire protection and plumbing design and construction.

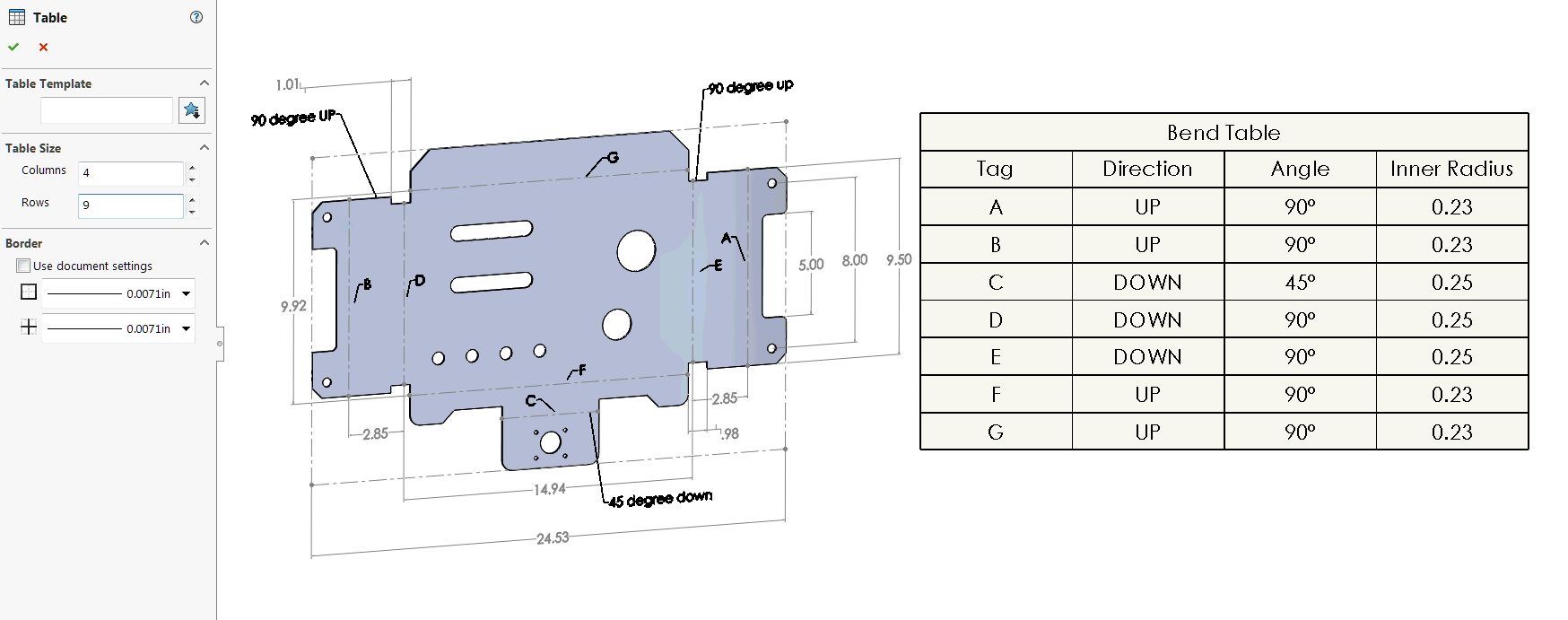

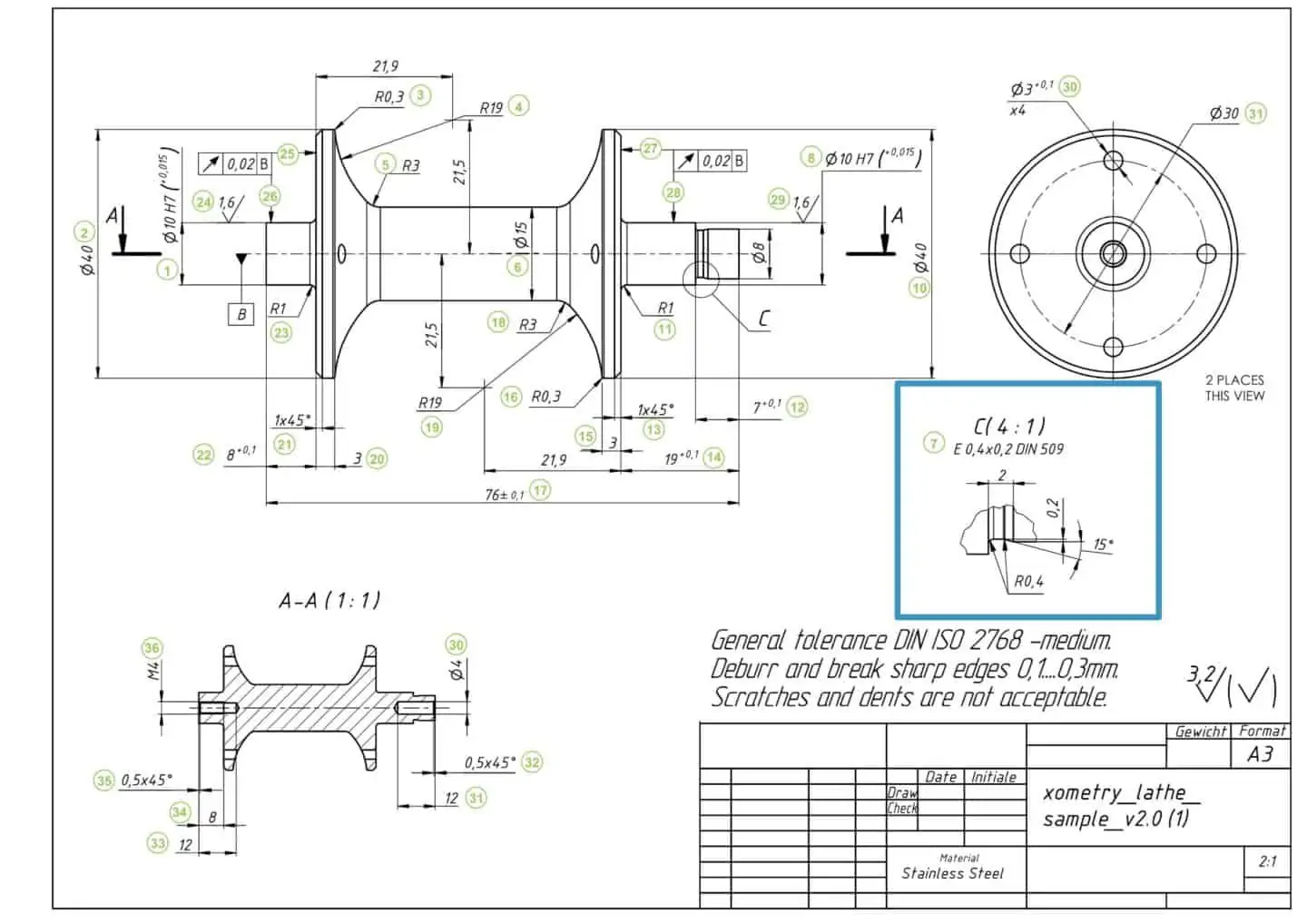

Sheet Metal Dimensional Drawing Example Vista Industrial Products Inc

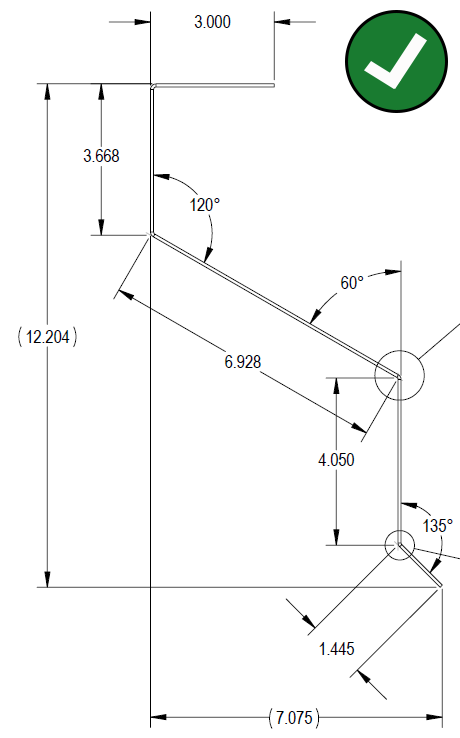

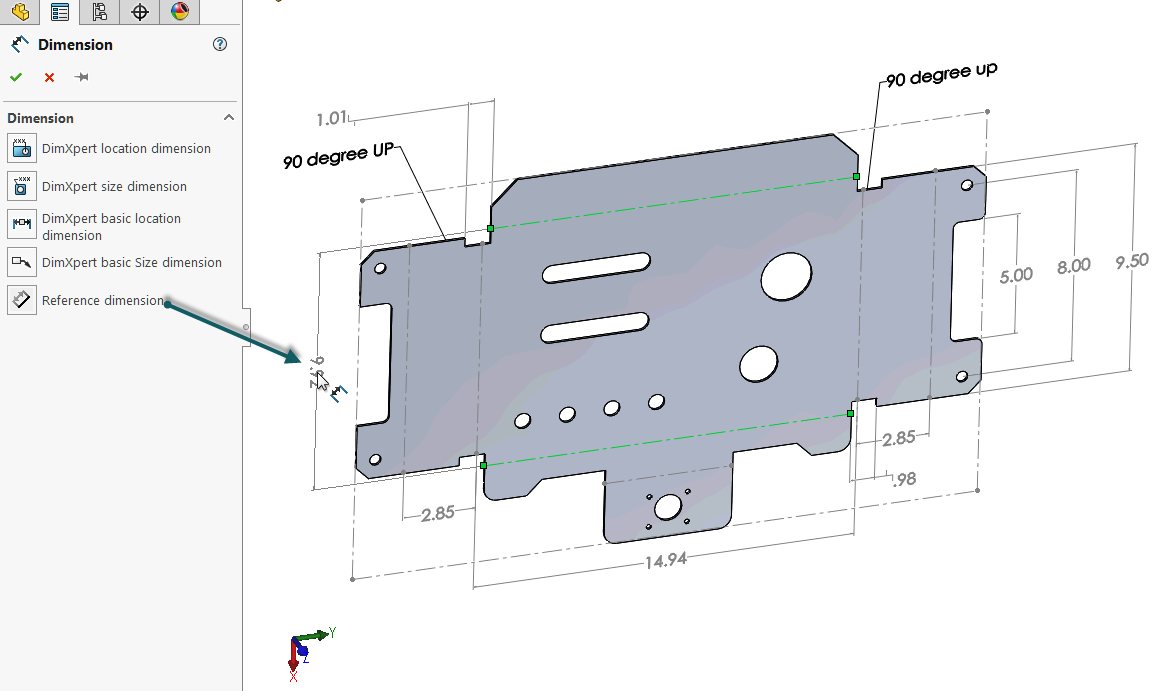

Dimensioning For Ease Of Manufacturing

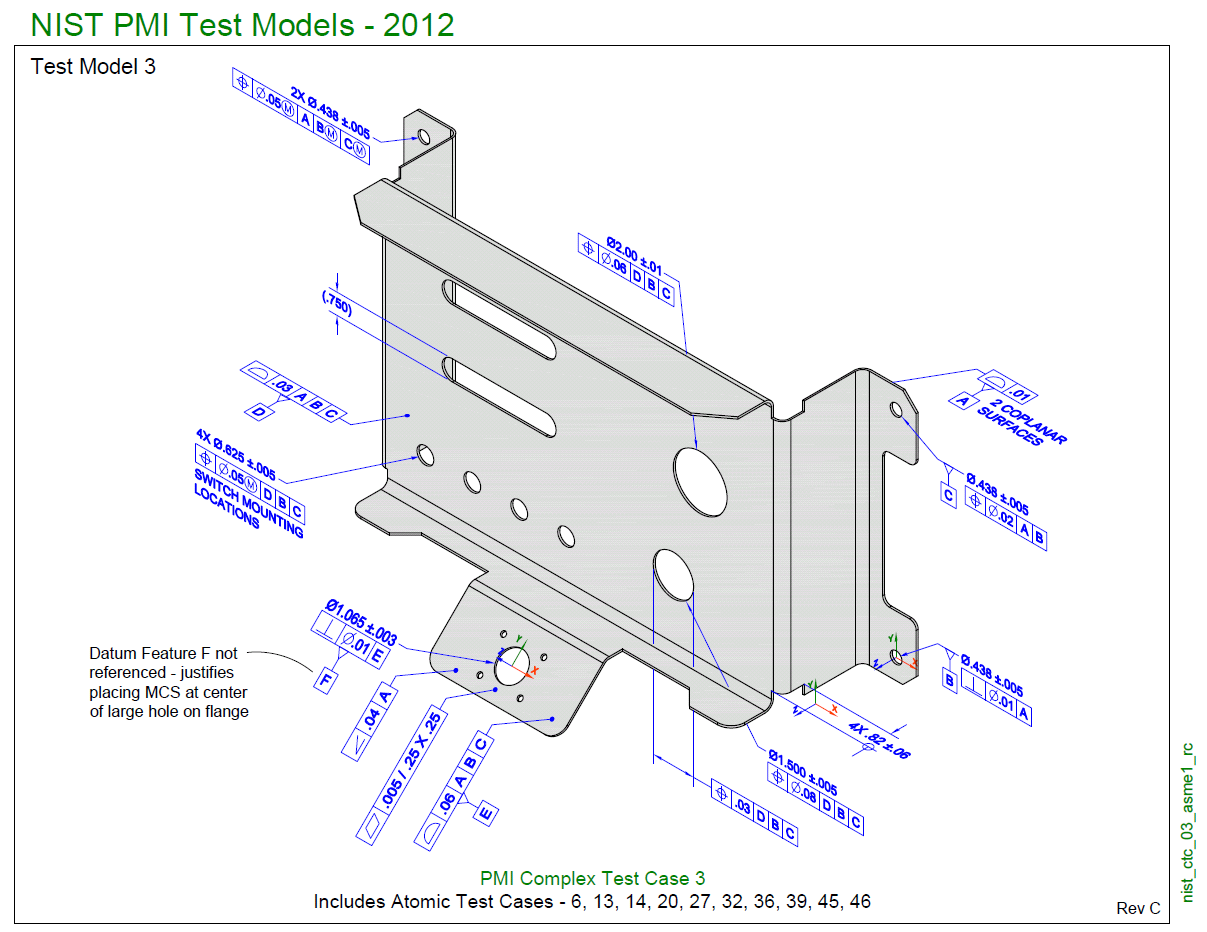

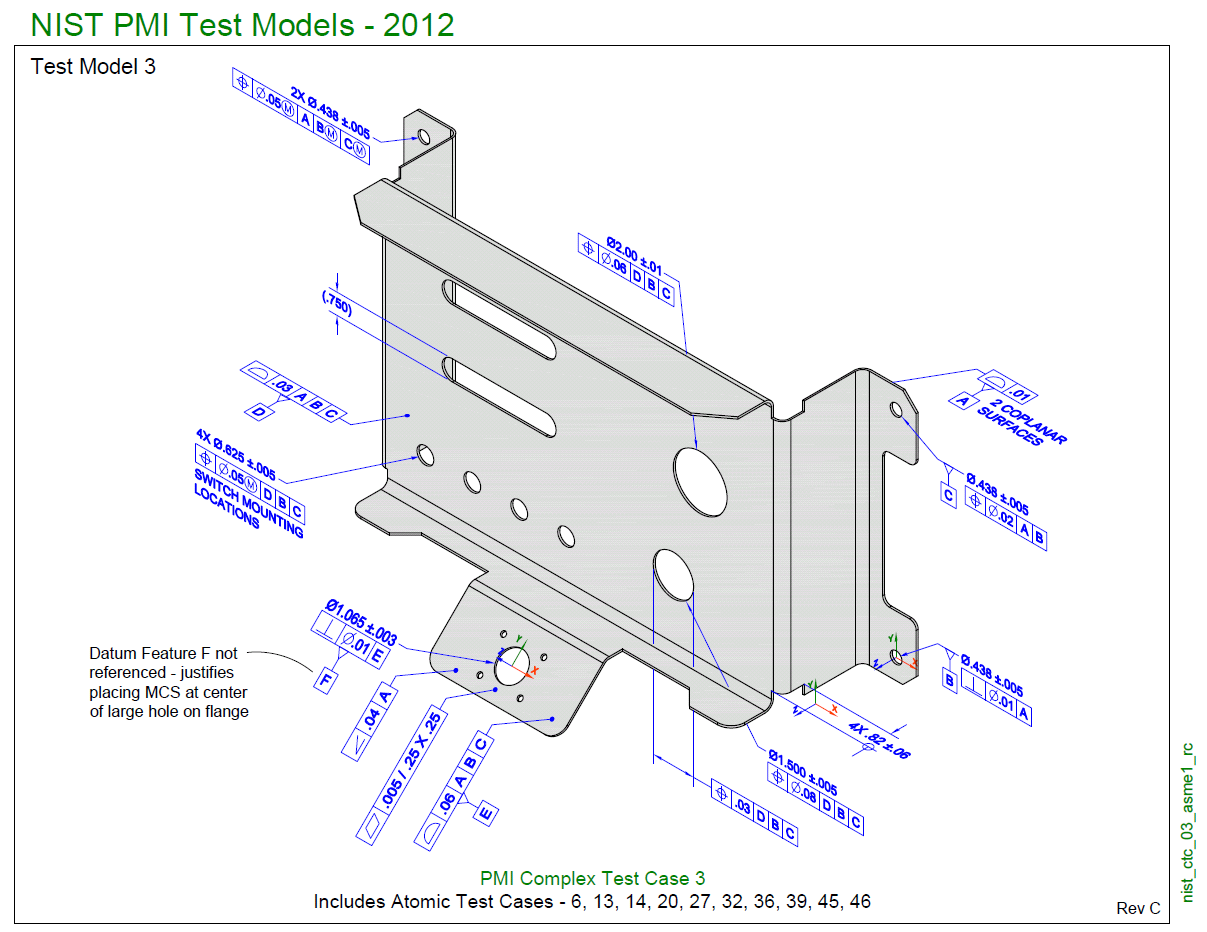

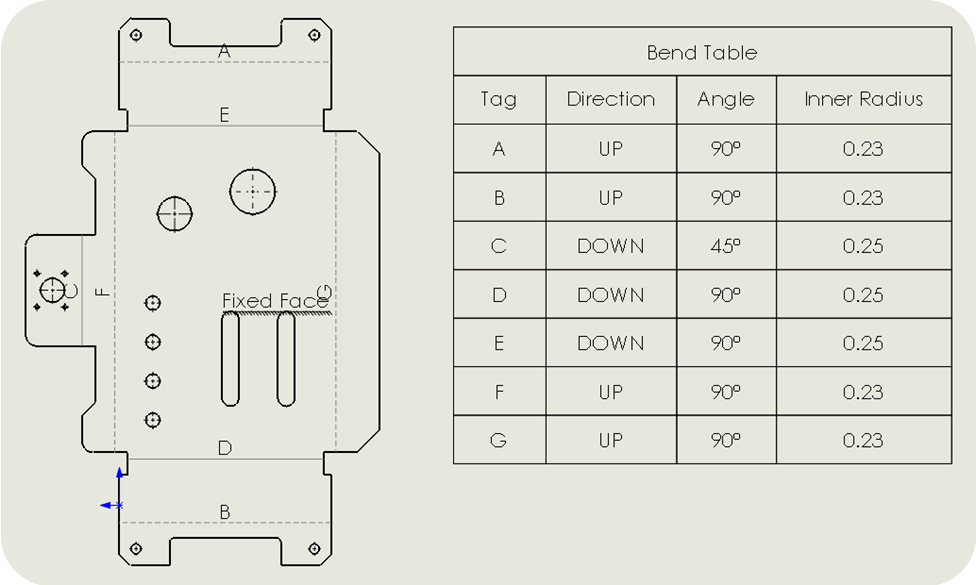

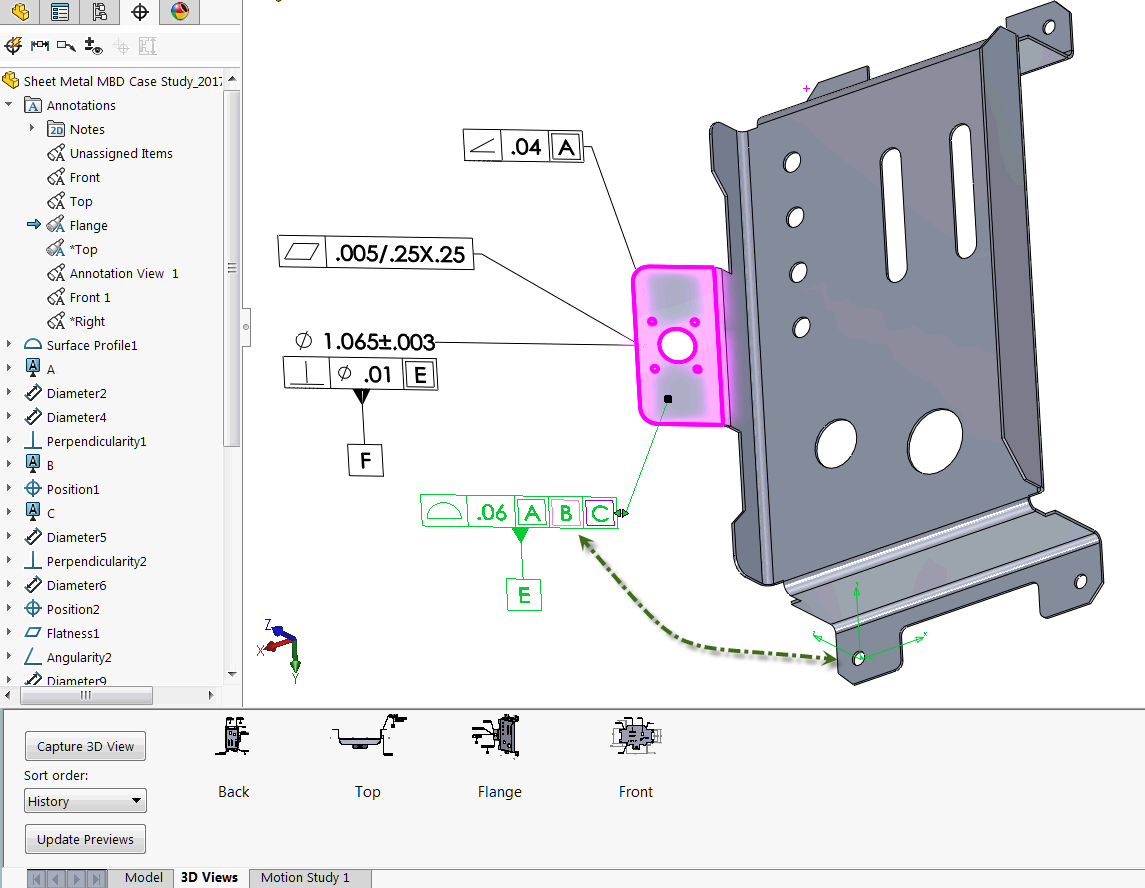

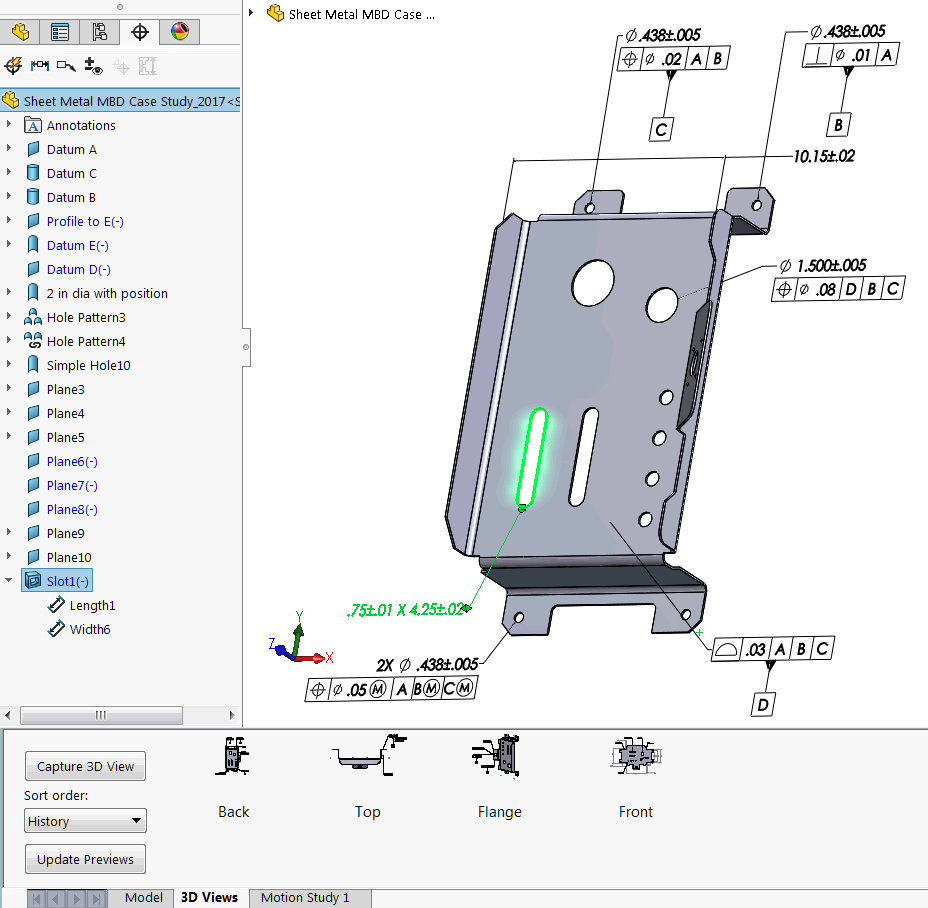

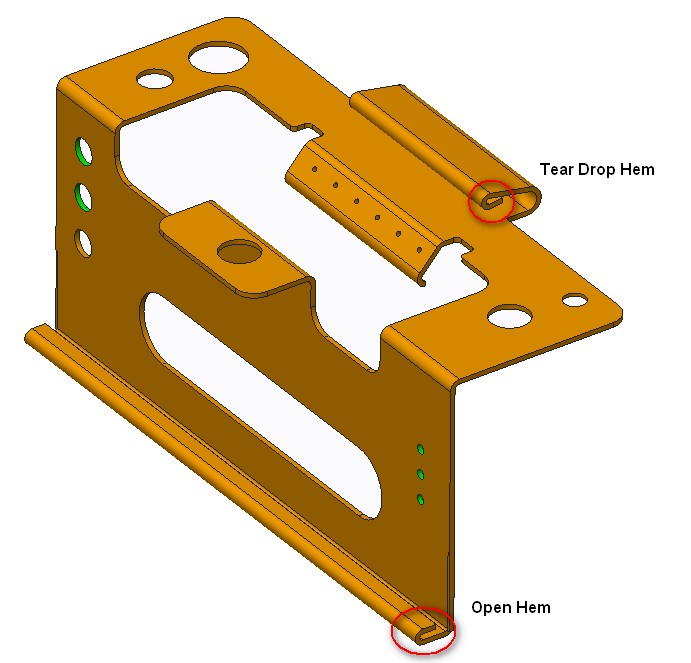

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

How To Present The Mbd Data Of Sheet Metal Parts Engineers Rule

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

Solidworks Sheet Metal Drawing Tutorial Bend Line Flat Pattern Unfolded Bend Table Punch Table Youtube

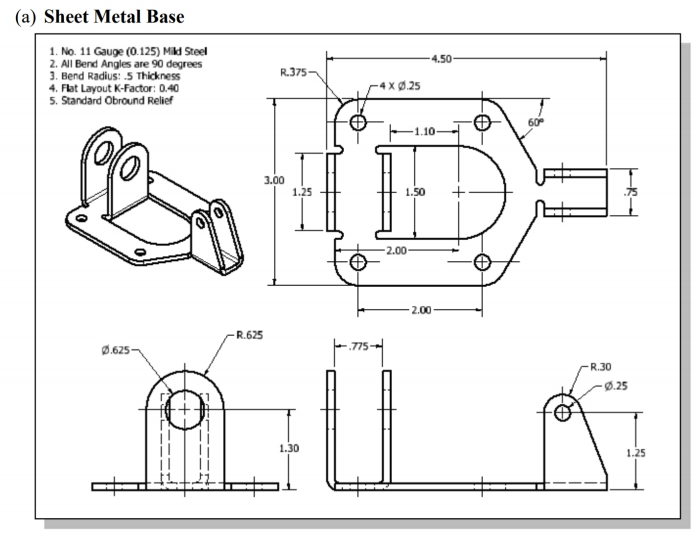

Solved A Sheet Metal Base 4 50 1 No 11 Gauge 0 125 Chegg Com

How To Prepare A Perfect Technical Drawing Xometry Europe

Sheet Metal Dimensional Drawing Example Vista Industrial Products Inc

Dimensioning For Ease Of Manufacturing

How To Prepare Drawings For Your Sheet Metal Supplier Komaspec

Sheet Metal Drafting Chapter 3 Wikisource The Free Online Library

Freelance Sheet Metal Design Services For Companies Cad Crowd

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

How To Define The Mbd Data Of Sheet Metal Parts Engineers Rule

Sheet Metal Design Guidelines Dfmpro

Sheet Metal Dimensional Drawing Example Vista Industrial Products Inc